The Mask Lab: The Solution for the risks in the Cement Industry

Cement is crucial for construction, forming the backbone of buildings, roads, and essential infrastructure. The industry’s crucial role in shaping modern societies is evident as urbanization and population growth fuel increasing demand. This drives innovation in production methods, sustainability, and environmental protection.

While essential for infrastructure development, the cement industry poses several significant hazards to workers and the environment. These hazards include:

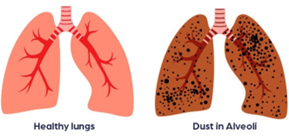

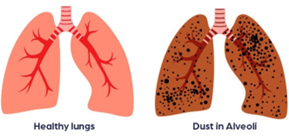

- Dust Exposure: Prolonged exposure to cement dust and airborne dust particles can lead to health issues such as silicosis and lung cancer.

- Noise Pollution: Machinery used in cement plants, such as crushers and conveyors, generates high levels of noise. Prolonged noise exposure can result in hearing loss and other auditory problems.

- Heat Stress: Cement production often occurs in kilns where temperatures are very high. Workers near kilns are at risk of heat stress, which can lead to heat exhaustion and heat stroke.

How does The Mask Lab come into the picture?

The Mask Lab (TML), a venture by Control Print Limited, has the latest manufacturing facility to produce top-quality respirators designed to protect from dust and other airborne contaminants.

Our products meet global standards with certifications including CE for PPE (Personal Protection Devices) and MD (Medical Devices), ISO 13485 for Quality Management Systems, and EN – 149 for FFP 1 and FFP 2, ensuring compliance and reliability in safety equipment production.

The Mask Lab has a range of Respirators, Safety Goggles and Earmuffs that cater to all the safety requirements-

TML Respirators:

- Particle Filtration: Our respirators like N95 or higher-rated respirators filter out the cement dust suspended in the air. They have a tight seal around the nose and mouth, ensuring that the air breathed in is filtered.

- Compliance with Safety Standards: Specific occupational health and safety regulations mandate the use of respirators in extremely dusty environments. We at TML ensure compliance with the IS 9473 standards.

- Protection from heat stress: In hot conditions, breathing in dusty air can strain the respiratory system. We provide respirators that help maintain a clearer breathing system, reducing the physiological strain associated with heat exposure.

EyeFence Safety Spectacles and Goggles:

- Chemical Splash Protection: EyeFence’s Safety Goggles provide a barrier to protect the eyes from splashes of chemicals in cement production. These chemicals cause irritation or burns to the eyes.

- User’s Comfort: Modern safety glasses are designed for comfort and have features such as anti-fog coatings and hard coating. Comfortable eyewear ensures continuous protection throughout the shifts.

- Compliance with Regulations: Our Safety goggles conform to the ANSI Z87.1, CE and CLI certifications.

EarFence Safety Spectacles and Goggles:

- Noise Reduction: TML’s Earmuffs are designed to reduce the intensity of noise reaching the ears. They typically provide a Noise Reduction Rating (NRR) of up to 31db which indicates the amount of noise reduction they can achieve.

- Compliance with Regulations: Our earmuffs are in accordance with the regulations. We have CE / EN352-1 and ANSI S3.19 certifications.

- Comfort and Longevity: We make sure our earmuffs provide comfort during extended wear. They fit different head sizes and are cushioned to reduce pressure on the ears in environments like cement plants.

Prioritizing the health and safety of workers in the Cement Industry is a non-negotiable. Therefore, respirators, eye and ear protective gears stand as essential components in mitigating risks in such work environments. By embracing these preventive measures, the industry not only safeguards its workforce but also cultivates a culture of responsibility, ensuring sustainable growth and well-being.